Desk

I built this desk in summer 2021 using primarily hand tools and a design adapted from Dinesen. I'd wanted to learn to build furniture within the space and noise constraints of a city apartment for several years, and when we moved into a new apartment with space for both a home office and woodworking, I had my opportunity. The project took about 4 months in total: from buying tools to building a workbench, to making the desk. I'm quite happy with the results. It's a bit rickety when moved, and the soft Douglas Fir is prone to dents, but it's wonderful having a desk built exactly to our needs, and we love the look of it.

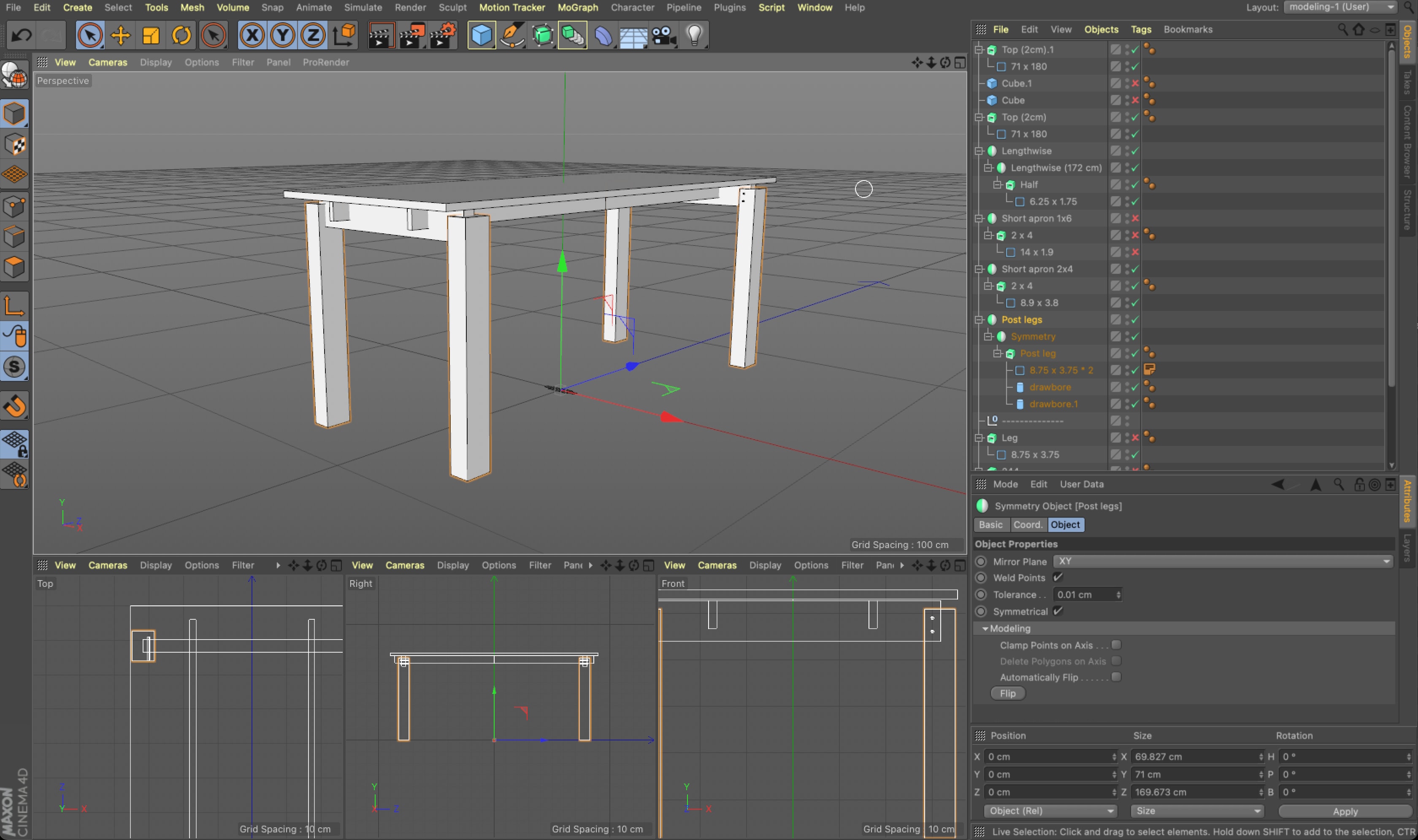

I selected the Dinesen as my reference design because it was both beautiful, and relatively simple in construction. I love how it elegantly creates visual interest from relatively simple joinery and a small number of pieces. Long apron boards poke out the end slightly, legs and apron overlap, etc. My favorite detail is the way the top floats slightly above the base.

After learning about the pros and cons of various species of wood, I chose to use Douglas Fir. I love the look of it, and as a softwood it promised to be easy to work with (as opposed to hardwoods like oak). Fir is also relatively sustainable: it's fast-growing and found in abundance in my home province of British Columbia. Using a common species enabled me to source my stock from Home Depot, carefully picking through stacks to find boards without knots, cups or bows.

Construction was a serious challenge. I quickly realized that I'd made my life difficult by choosing to build a large piece of furniture (versus, say, a stool). Large size + inexperience + perfectionism were a dangerous combination. I'd been careful to choose good boards, but they still needed to be squared up where edges met, at a minimum. Without an electric planer or jointer, this was done by hand, using a Stanley jack plane, and some mediocre clamping arragements on my (too small) workbench.

In some cases, tools needed to be made from scratch before work could progress. A workbench was the first thing that was built. I needed a surface on which I could do everything from sawing to planing, and that would fit within the space constraints of our apartment's patio and storage locker. After much research I went with a low roman workbench.

The top was created from four 7" boards. The edges were first made square by match planing. Because of their size, this needed to be done using the bench surface as a giant shooting board. The prepped boards were then glued into a single panel using pipe clamps and cauls.

I'm happy with the end result. I was able to build a piece of furniture that we love the look of, that fits both our needs and our available space perfectly, and I picked up a bunch of useful skills along the way. I wish it hadn't taken as long as it did, and if I had to do it again I'd probably use a wood that's less prone to denting, but overall I'm very pleased with this as a first project.